Quality Control

The highest level of quality control in line with modern standards

At Ferometal – prerada d.o.o., quality control is not a final step but an integral part of every

stage of production. Each component undergoes clearly defined measurement procedures,

supported by advanced 3D measuring systems and a certified quality management system.

Through a combination of precise CNC machining, advanced measuring equipment, and a skilled team, we ensure that every manufactured part meets or exceeds drawing requirements, specifications, and international standards. Special attention is given to repeatability, process traceability, and documentation of all key measurement results.

Through a combination of precise CNC machining, advanced measuring equipment, and a skilled team, we ensure that every manufactured part meets or exceeds drawing requirements, specifications, and international standards. Special attention is given to repeatability, process traceability, and documentation of all key measurement results.

ISO 9001

ISO 14001

OHSAS 18001

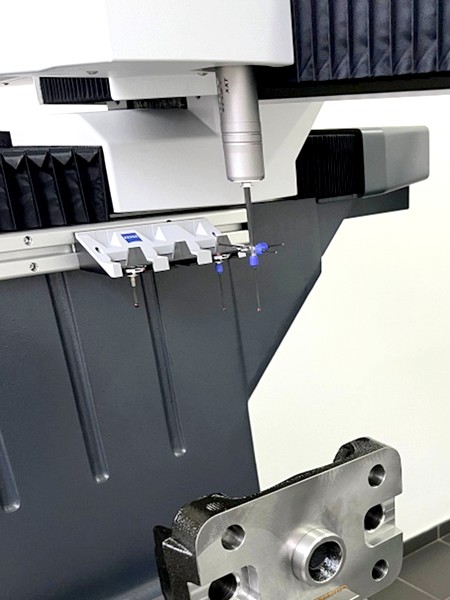

ZEISS DuraMax CMM

Industrial 3D measuring machine for series and prototype inspection

The ZEISS DuraMax CMM enables highly precise 3D measurement of complex geometries, freeform surfaces, and tight tolerances. This approach ensures stable, repeatable, and fully traceable quality control in accordance with the strictest industry standards.

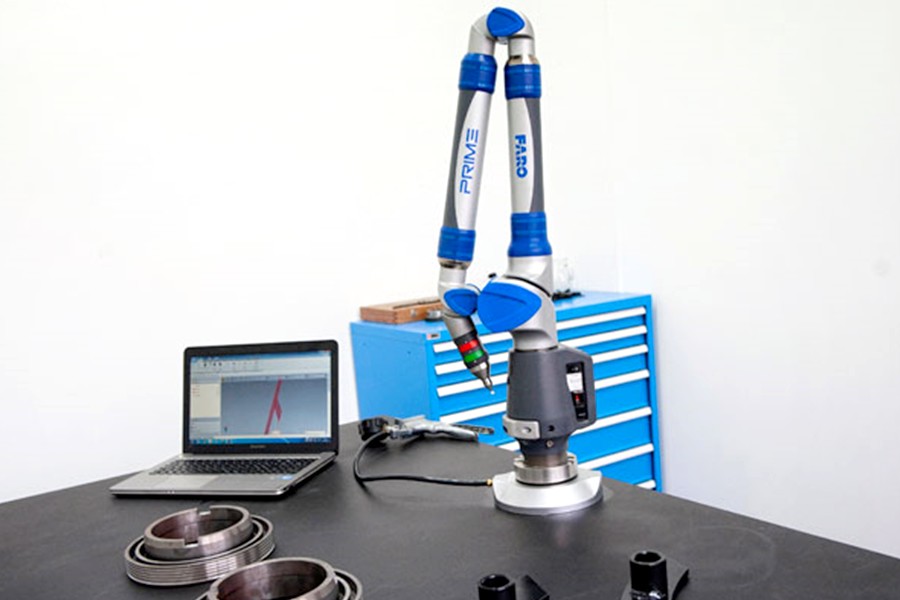

FARO Prime 3D Measuring Arm

Flexible measurement and quality control directly on the production floor

The FARO Prime 3D measuring arm is used for fast and accurate inspection of parts directly in the production environment. The system’s mobility allows measurements to be performed at the exact point where the product is created, reducing reaction times and enhancing process reliability.