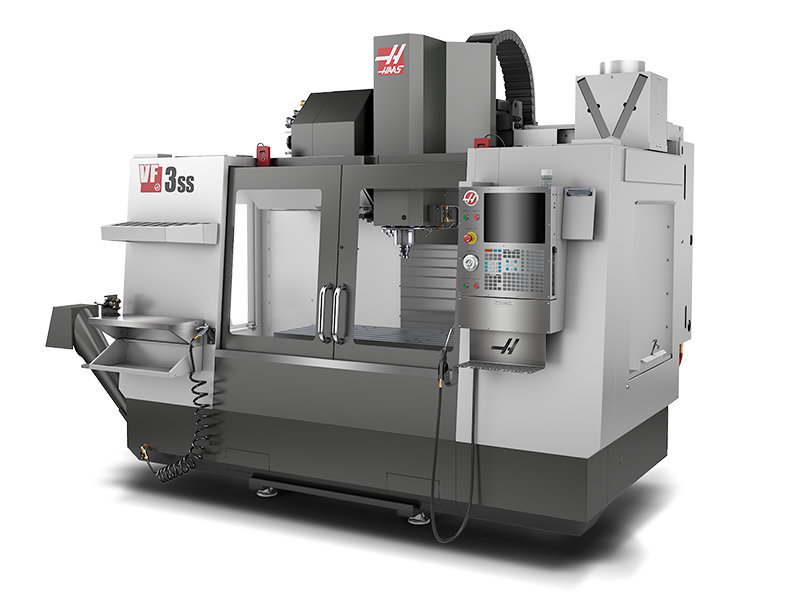

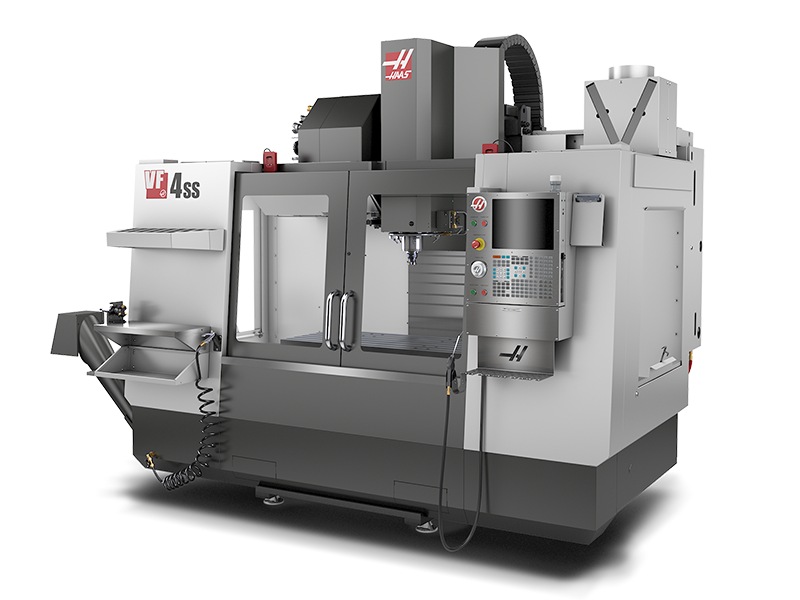

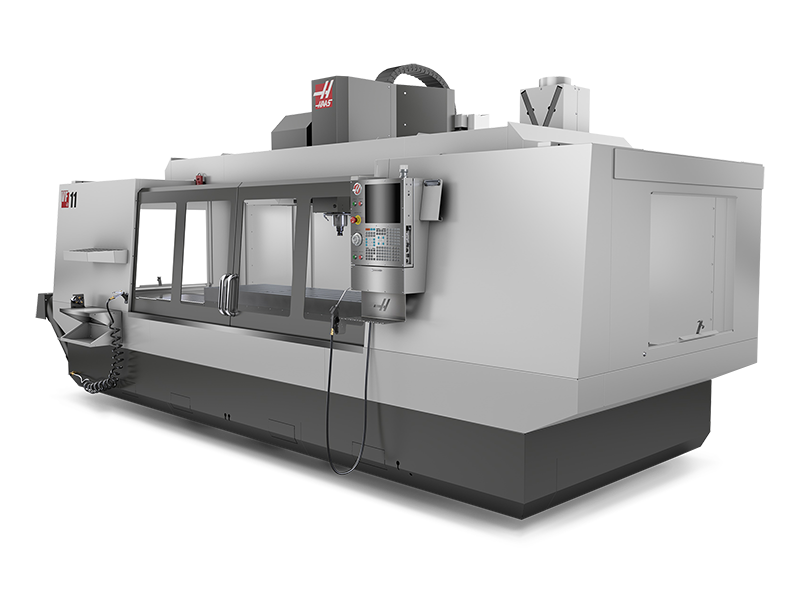

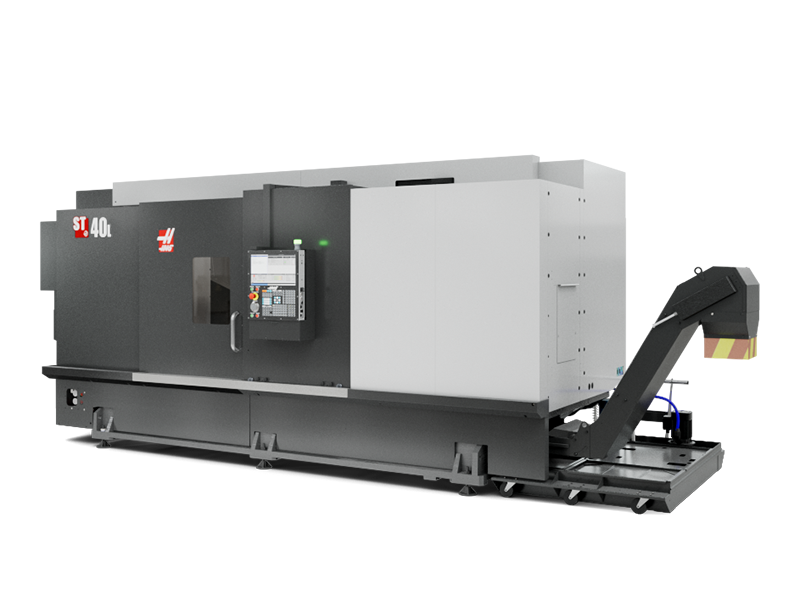

The CNC Power Behind Modern Industrial Technology

Production Capabilities

CNC machining up to ±0.01 mm tolerance

21 CNC machines

Production facility 2500 m2

Specialized Metal Production

CNC milling and turning

CO2 and electric welding

Quality control